Ultrashort laser pulses support fiber-reinforced components

source:Optics.org

keywords: Ultrashort laser pulses

Time:2016-07-25

Fiber-reinforced materials, having been prevalent in the aerospace industry for many years, are now being used in numerous other sectors such as automotive construction, medical engineering, and building construction. As a result, the demand for materials and processing methods is also growing fast.

Composite materials made of glass or carbon fiber are characterized by low specific weight combined with outstanding mechanical characteristics.

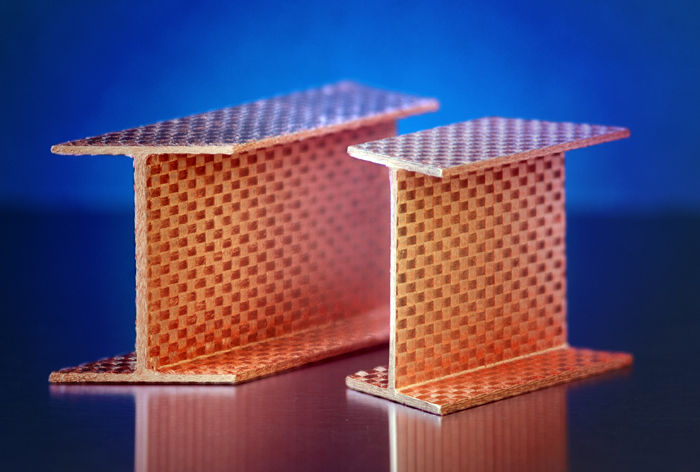

Laser-pretreated and subsequently metalized 3D CFRP component.

Fiber-reinforced components are already processed in industrial mass production. And although these material have certain limitations regarding the manufacturing processes that can be used, these can be overcome through the clever use of laser processes.

The high-quality mechanical characteristics of fiber-reinforced components stem from a load-adapted composition of polymer matrix and fibers. In order to remove the matrix material close to the surface, the Fraunhofer Institute for Laser Technology (ILT) developed a method that allows the outer layers of the surrounding polymer matrix to be removed without damaging the underlying fibers.

Using ultrashort pulsed laser radiation, the matrixmaterial– which usually consists of epoxy resin – can be processed with local and depth-selective ablation and can even be removed completely. An adapted process control allows the surface to be processed in such a way that the adjacent fibers do not suffer any damage.

Environmentally-friendly

“This is achieved through a local and selective adjustment of laser power and beam guidance,” explained Christian Hördemann, a scientist at Fraunhofer ILT. "As a result, even complex geometries and 3D components can be processed with the laser. This ability to process surfaces without disturbing the load-oriented processed fibers is especially interesting for the aerospace industry."

A possible field of application for the new method is in preparing a solid joint between composite materials and adjacent components. In a subsequent step, heterogeneous plastics can be sprayed directly onto the exposed fiber structure, whereby they surround the fibers and can be mated in a form-closed joint. Moreover, the method is also suitable for subsequent work steps using adhesion. For certain applications, CFRP and other plastic components must be coated with conductive layers.

Working together with the Fraunhofer IST, the Fraunhofer ILT co-developed the method so that plastic components can be supplied with a well-bonded copper layer without using toxic Cr(VI) chemicals. Also a direct metallization is possible. The method is used for highly loaded antenna bodies as well as for chrome plating of decorative lightweight components.

- RoboSense is to Produce the First Chinese Multi-beam LiDAR

- China is to Accelerate the Development of Laser Hardening Application

- Han’s Laser Buys Canadian Fiber Specialist CorActive

- SPI Lasers continues it expansion in China, appointing a dedicated Sales Director

- Laser Coating Removal Robot for Aircraft

FISBA exhibits Customized Solutions for Minimally Invasive Medical Endoscopic Devices at COMPAMED in

FISBA exhibits Customized Solutions for Minimally Invasive Medical Endoscopic Devices at COMPAMED in New Active Alignment System for the Coupling of Photonic Structures to Fiber Arrays

New Active Alignment System for the Coupling of Photonic Structures to Fiber Arrays A new industrial compression module by Amplitude

A new industrial compression module by Amplitude Menhir Photonics Introduces the MENHIR-1550 The Industry's First Turnkey Femtosecond Laser of

Menhir Photonics Introduces the MENHIR-1550 The Industry's First Turnkey Femtosecond Laser of Shenzhen DNE Laser introduced new generation D-FAST cutting machine (12000 W)

more>>

Shenzhen DNE Laser introduced new generation D-FAST cutting machine (12000 W)

more>>